Ventilation units are designed for the supply of fresh preheated air and exhaust of polluted air from the living areas of apartments and family houses. ROVENTO units are especially suitable for ventilation of family houses, both brick and wooden buildings.

The company ELEKTRODESIGN ventilators, s.r.o. is not only a successful supplier in the range of fans and air conditioning accessories, but also a manufacturer and supplier of heat recovery and regeneration units for commercial and residential use, including its own control systems. In the area of ventilation units for residential use, ELEKTRODESIGN ventilators, s.r.o. offers a range of ROVENTO® ventilation units.

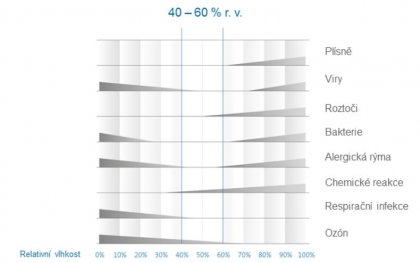

The ROVENTO® units are equipped with a rotary enthalpy regenerative heat exchanger for the reverse transfer of heat (thermal efficiency up to 84%) and moisture from the exhaust air to the incoming fresh air. By transferring the moisture to the fresh ventilation air, ROVENTO® units can prevent excessive drying of the air in the rooms of houses (especially in wooden buildings with diffusely open envelope construction) during the operation of the ventilation system. It is a known fact from experience that in timber buildings ventilated by heat recovery units without moisture transfer, excessive drying of the indoor air results in increased morbidity for the occupants. From a hygienic point of view, the range of optimum relative humidity in the living spaces of houses is recommended to be between 40-60% r.h. The main task of ventilation units is to keep the relative humidity within optimum limits. In the relative humidity range of 40 to 60 % RH, there is no excessive presence of mould, mites, bacteria and other harmful substances in the ventilated space. The effect of the environment on the human body as a function of relative humidity is clearly illustrated in the Sterling-Scofield diagram.

ROVENTO® ventilation units are equipped with a rotary regenerative heat exchanger with a hygroscopic layer consisting of ZEOLIT molecular sieve for moisture transfer. A special layer based on synthetic Zeolite deposited on an aluminium carrier uses the latest developments in nanotechnology. The main advantage is the clearly defined molecular structure. The Zeolite layer transfers water vapour molecules to the maximum extent possible while preventing the sorption and transfer of odour molecules and VOCs. The technology uses a molecular sieve with an effective diameter of 4×10-10 m, which sorbs water vapour molecules with a diameter of 3.2×10-10 m. The size of commonly occurring odours and VOCs is 7×10-10 m, so sorption of these unwanted substances in the zeolite sieve is eliminated.

The main advantages of rotary regenerative heat exchangers with a zeolite bed are as follows:

- high efficiency of moisture transfer (up to 80%)

- no odour and VOC transfer

- lower risk of rotor freezing in winter

- low pressure drop and associated lower electrical input of the ventilation unit fans

ROVENTO® ventilation units are available in 3 sizes with a maximum air flow of 220 m3/h, 320 m3/h, 520 m3/h. The casing of the unit is frameless and consists of 25 mm thick sandwich insulated panels. The unit is designed for installation in an indoor environment (e.g. in a technical room) on the floor or under the ceiling.

The ROVENTO® ventilation units are equipped with fans with EC motors with high efficiency. The units can be optionally equipped with electric reheating, which is fitted with a two-stage overheating protection by thermostats as standard. On the supply and extract side, the unit is equipped with G4 (ISO Coarse 60%) or M5 (ISO ePM10 50%) filters or F7 (ISO ePM2.5 70%) pollen filters.

The ROVENTO® ventilation units are completely manufactured in the Czech Republic and are equipped with the Minireg® control system developed by ELEKTRODESIGN ventilators, s.r.o. The control of the unit is possible from the room controller, on which it is possible to select 3 stages of air flow, or 3 stages of output temperature (for units with additional electric reheating). The room controller also allows the unit to be switched on and off and to signal faults and service. A touch screen form of controller is also available with enhanced control and monitoring options for the unit. The controller is of the Plug&Play type, once the controller is connected to the unit, the unit is fully functional and operational.

The ROVENTO® ventilation units comply with energy class B.