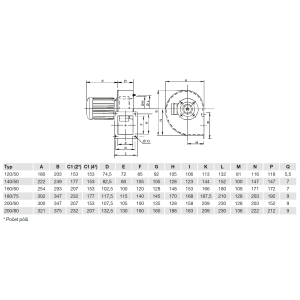

Cabinet

is made of electrically welded sheet metal and is coated with a durable epoxy-polyester paint in grey colour. The spiral enclosure is supplied in the LG 270 position as standard, the position can be changed on installation. The fans are designed to permanently convey warm air up to +80ºC or +110ºC, free of hazardous substances.

Running wheel

with forward curved blades is made of electroplated steel plate. The impeller is dynamically balanced according to ISO 1940.

Motor

is an asynchronous induction motor, housed outside the air stream, and is manufactured to IEC 34-1. The motor insulation is according to type class B or F, protection IP44 or IP55. The motor has lifetime grease-filled ball bearings. Two-speed motors or explosion-proof versions can be supplied on request.

Clamps

is located on the engine.

Speed control

for selected types by electronic or transformer regulators by changing the voltage or frequency converter.

Noise

The tables show the sound pressure in the free acoustic field at a distance of 1.5 m at the discharge at maximum flow.

Mounting

The position of the discharge can be changed at the installation. The enclosure must not transmit mechanical stresses from the pipework. A flexible connection to the pipework must be used. Before installation, it is important to check that the electrical parameters of the product, as indicated on the label (voltage, power, frequency, etc.), correspond to the values of the local network.

Instructions

The fans are suitable for general HVAC and OEM applications where exhaust of hot air without hazardous substances is required. CMB/CMT fans can be used alone or incorporated into other groups of machinery designed for air extraction or supply, including forced air ventilation in industry and engine air cooling.

Share on Facebook

Share on Facebook Tweet

Tweet Send email

Send email