Cabinet

Patented ISOSTREAM® modular system with 45 mm thick wall panels made of galvanized steel sheet with external painting in RAL9002 (grey-white). The panels are internally filled with sound and thermal insulation made of non-combustible glass mineral wool. For ease of servicing, the unit cabinet is equipped with an opening door with locks. The square throats are prepared for the fitting of a 20 mm frame silencing insert. The frame of the unit is made of aluminium profiles, the wall panels are screwed into the frame. The condensate outlets from the heat exchanger and condenser are always located in the bottom panel of the unit and are ready for connection to the odour trap. At the customer's request, the unit shell can be provided with atypical surface protection with higher corrosion resistance.

Fans

A fan with backward curved blades is mounted on both the supply and exhaust sides of the unit. The impeller is made of composite material and is statically and dynamically balanced.

Motors

An EC motor is directly mounted on the fan impeller. The fan motor can be continuously controlled by an external 0...10 V signal. The motor is equipped with its own built-in thermal protection. Motor efficiency class IE4, motor protection IP54.

Regenerator

Rotary regenerative heat exchanger for heat transfer or for transferring heat and moisture simultaneously. The exchanger is designed to operate at ambient temperatures of -20 °C to +55 °C. The rotor is alternately wound from a flat and radlated layer of aluminium foil. The standard wave height is 1.6 mm. The rotor casing is made of galvanised support profiles. A brush seal provides the seal between the rotor and the casing; for sizes 6000 and 7800 the rotor is equipped with a flushing chamber. On request, a labyrinth rotor seal can be fitted with an average leakage value below 1.5% of the volume flow rate. The rotary heat exchanger drive consists of an electric motor with worm gear, pulley and belt. The supply voltage of the electric motor is 1×230 V/50 Hz or 3×230 V/50 Hz.

Filters

There can be 2 filter cartridge elements of different filtration classes of 48 mm thickness or 1 filter element of 96 mm thickness (only one filter of 48 mm thickness can be placed in size 800) for fresh air intake and exhaust air intake. Filters are available in filtration classes from G4 to F9. Access to the filters is via the inspection door on the service side of the unit. In the case of multi-stage filtration, the unit can be supplemented with MFL filter cartridges with MFR filter inserts, which are designed for installation in pipes.

Electrical connection

The power supply voltage of the units is 1×230 V/50 Hz or 3×400 V/50 Hz and depends on the unit equipment. Supply cables, cables to sensors, power cables to fans are fed into the unit through plastic grommets in the unit wall. Inside the unit, rubber grommets with membrane are provided for cable routing.

Regulation

The unit is equipped with Digireg® control as standard according to the unit configuration. In case the unit is equipped with MaR system directly from the factory, all sensors and actuators are electrically connected and tested. The control cabinet is located on the wall of the unit, according to the actual space requirements of the specific project (the location of the MaR control cabinet must be specified in the order).

Mounting

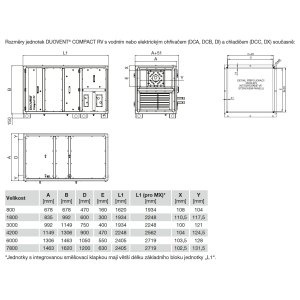

in vertical position (on the floor). The specific location of the throat in relation to the service side of the unit must be specified according to the table of throat location options. A prescribed service space must be maintained in front of the unit for service intervention, filter changes, etc. Space must be provided below the unit for the installation of a condensate drain trap. The unit must be installed with a 1% slope towards the condensate drain. The HVAC piping is connected to the prepared rectangular sockets - it is recommended to install flexible sleeves between the sockets and the unit to eliminate vibration transfer from the unit to the piping. The rectangular throats are fitted with a standard 20 mm flange. Wall-mounted outdoor versions of the units (ROOFPACK-A and ROOFPACK-B) must be consulted with the factory before ordering.

Noise

The sound power levels shown in the tables represent the sound power levels at the individual throats of the unit with weighting filter correction A, the sound power level of the entire unit shell. Acoustic parameters are within ±3 dB.

Variants

Individual unit variants are differentiated according to the equipment by means of a code. Atypical unit designs that fall outside the set of supplied variants must be consulted with the factory before ordering.

Air conditioning accessories

- Sonoflex®, Thermoflex® - flexible hoses and fittings

- SPIRO - circular spiro-pipes and fittings

- KAA, IAE - flexible couplings

- MAA, MTS - silencers

- RSK, TSK - check valves

- MSK, IJK - throttling and mixing valves

- plate valves, anemostats, nozzles, louvers

- rain shutters

- MBE, IBE, IBW, MBW - electric and water heaters for circular and square ducts

- MKW, IKW, IKF, MKF - water coolers and direct evaporators for circular and square ducts

- MFL, IFL - filter cartridges for circular and square ducts

- ESU - mixing nodes

EL Accessories

- Digireg® - digital control system for both heating and cooling units, touch screen controller.

- JTR - triac switch for electric heater power control

- HIG, HYG - hygrostats

- EDF-CO2, SQA - CO2 sensors

- RTR - thermostats

- DTS PSA - pressure sensors

- actuators

- AIRSENS - air quality sensors

Warranty Terms

The DUOVENT® COMPACT RV, including the DVAV, DCAV and DCOP control system, must be put into operation exclusively by the Seller or by a person designated by the Seller. Failure to comply with this condition shall result in the termination of the Buyer's rights under the defective performance and the Quality Warranty. Further conditions are set out in the Seller's Complaints Procedure.

Information

The unit is designed for ventilation of commercial premises. Mounting variants allow for adaptation to building requirements. The unit is designed for permanent operation.

Share on Facebook

Share on Facebook Tweet

Tweet Send email

Send email