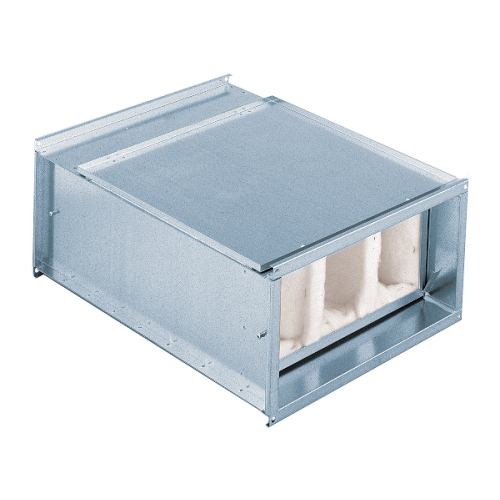

Cabinet

The fan is made of galvanized steel sheet, sandwich design. The enclosure is coated with a 50 mm thick layer of soundproofing material. The impeller motor is mounted on a service door allowing easy cleaning and maintenance. The enclosure is fitted with flanges for mounting on square pipes.

Circulating wheel

The impeller is radial with backward curved blades and is made of galvanized steel plate. It is statically and dynamically balanced.

Motor

is asynchronous with a resistive armature. The motors are fitted with a thermal fuse as standard, the windings are in a moisture proof finish with Class F insulation. The ball bearings are grease filled for life. IP54 protection.

Square box

is made of black plastic as standard, is loosely connected to the motor supply cable and can be screwed to an easily accessible location on the enclosure with self-tapping screws.

Mounting

in every position of the fan, preferably with the axis of the motor vertical, with regard to the inspection activity and the possibility of opening the inspection door.

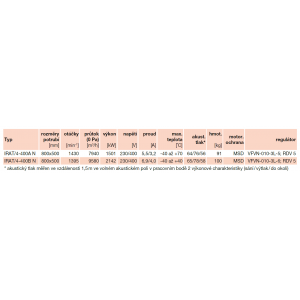

Speed control

is carried out by transformer regulators by changing the voltage or by frequency converters. Frequency converters are preferably recommended.

Rotation direction

is indicated by an arrow stuck on the cabinet. The direction of rotation must be checked after commissioning, if the direction of rotation is reversed, the phase sequence must be changed.

Instructions

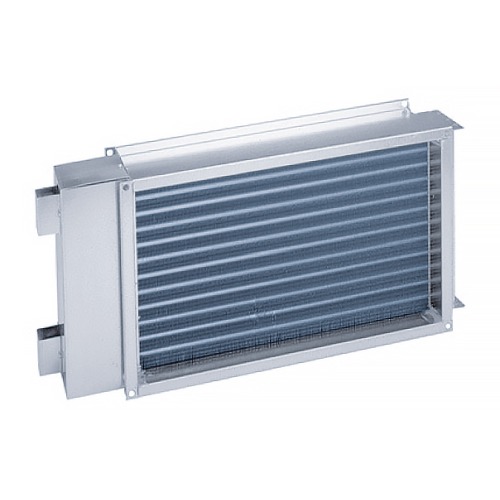

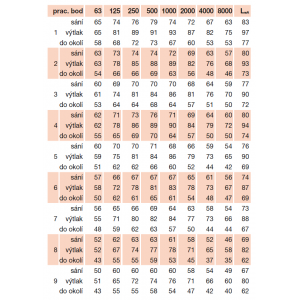

The fans are suitable for general air handling applications where low installation height and low fan noise are advantageous. The fans are suitable for ventilation of restaurants, hospitals, sports halls, warehouses and production areas due to IP54 protection and higher operating temperature up to 70 ˚C. They can be preferably used in combination with heat recovery heat exchangers (K 3.2).

Share on Facebook

Share on Facebook Tweet

Tweet Send email

Send email