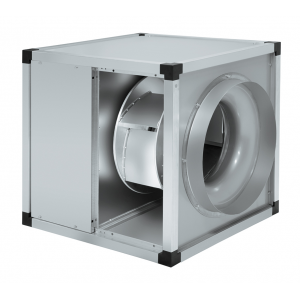

Cabinet

It is made of galvanized steel sheet, sandwich design. The cabinet is internally coated with a layer of soundproofing material. The fan is mounted in the enclosure on sprung profiles to reduce vibration transmission. A circular inlet is fitted on the cabinet for connection of flexible hoses or circular ducting. There is a square hole on the discharge where a circular pipe reducer, supplied separately, can be connected. The cabinet contains a tray for the drainage of the fat condensate, the condensate drain must be mounted in accordance with the position of the fan and the appropriate inclination of the fan towards the throat must be selected.

Running wheel

is radial with backward curved blades. The impeller is free-running, without spiral housing, statically and dynamically balanced.

Motor

is asynchronous with resistive armature. KABB fan motors are 1-phase for 230 V, KABT are 3-phase for 230/400 V or 3-phase for 400 V. The motors are equipped with a thermal fuse as standard, the windings are in a moisture-proof design with insulation class F. Max. ambient temperature of the motor 100 °C KABB (KABB/4-3000 70 °C, KABB/4-4000 50 °C, KABB/4-6000 40 °C), 40 °C KABT . The sealed and maintenance-free ball bearings are grease filled for life. IP55 protection.

Clamps

It is made of black plastic as standard, is loosely connected to the motor supply cable and can be screwed to an easily accessible location on the enclosure with self-tapping screws. Cable length 0,8 m, IP55 protection.

Mounting

is carried out exclusively with the motor axis horizontal and the condensate bath underneath, taking into account the design, fan operation and inspection activities.

Instructions

Fans are suitable for air handling applications where low fan noise is advantageous. The fans are particularly suitable for large capacity kitchens, ventilation of restaurants, sports halls, hospitals, warehouses and swimming pools.

Share on Facebook

Share on Facebook Tweet

Tweet Send email

Send email