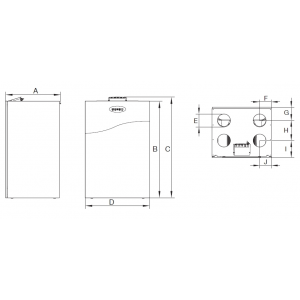

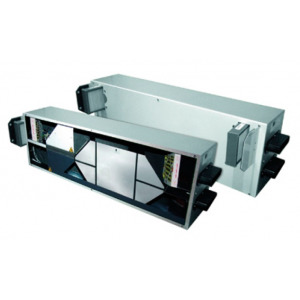

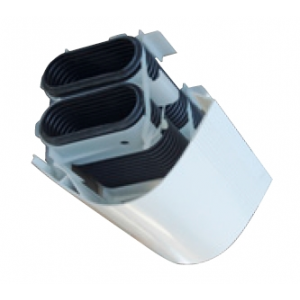

Cabinet

The cabinet is made of extruded polypropylene, the shell is made of painted steel sheet. Oval necks are placed on the short surfaces of the cabinet. The condensate drain is positioned so that the unit can be mounted horizontally or vertically. Internal parts and inlet throats are made of highly stable polyethylene.

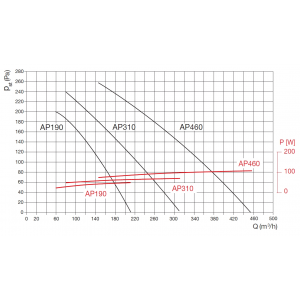

Fans

Fans are radial with backward curved blades on both supply and extract. Electronics and fans are easily accessible for servicing.

Motor

The motor is DC with high efficiency and low power consumption. The supply voltage is 230 V/50 Hz. Protection rating IP 44.

Recuperation

The countercurrent plate Al heat exchanger has an efficiency range of up to 85%.

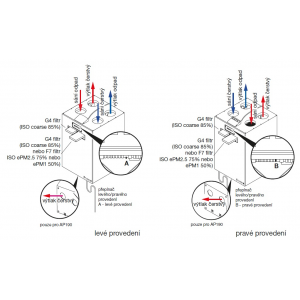

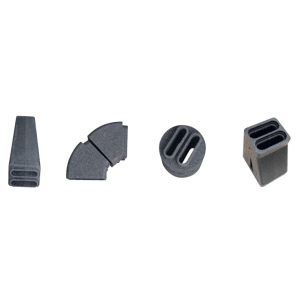

Filter

G4 plate fittings are standard on the inlet and discharge (F7 can be ordered). No tools are required to remove the fittings.

El. connection

A power cord with plug is routed out of the unit. The remote control is connected via a data cable.

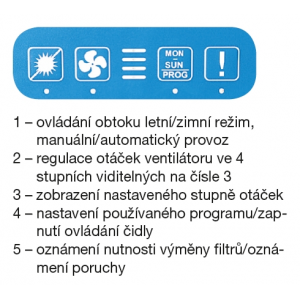

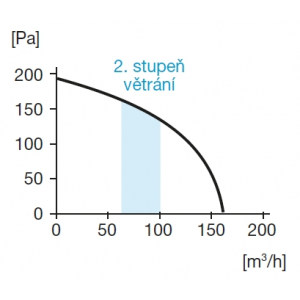

Speed control

Speed control is three-stage, performed by remote control. 20 daily or weekly programs can be set.

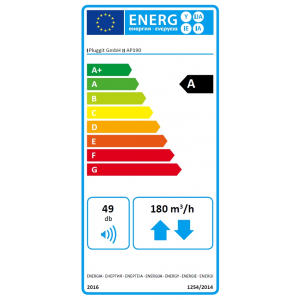

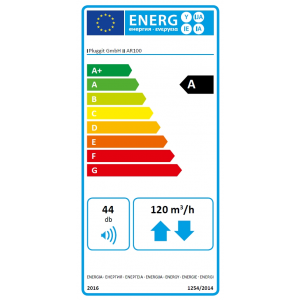

Noise

The unit is extremely quiet thanks to its special design and the use of an EC motor fan. The acoustic pressure is given in the table.

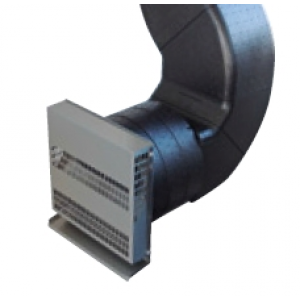

Mounting

Mounting in vertical and horizontal side position. Wall mounted. Clear space is required in front of the unit to allow removal of filters. For ceiling and floor mounting, the optimum gradient must be maintained to ensure condensate drainage. The condensate drain connection is made via a siphon odour trap to the waste line or rainwater outlet. Condensate drainage is by 1/2" hose.

Accessories

- remote control (included)

- Plugflex PK150 (25 m) pluggit duct system

- double bracket for PK150 - RHDK150

- Plugflex PK200 (10 m) pluggit duct

- Izoplug compact IPC200 insulated duct

- RVT150 switchboard/socket

- wall passage set IPCWD

- BS090- arch150

- inlet element including control and router iQoanda RKO150

- drain element/set REV150

- Y fitting YS200-150-150

- T fitting TS150-200-150

- cover channel PPE/PPD

- facade inlet/outlet grille IPCWH

- connection spigot to AR100 - IPCAS

Instructions

Due to the high efficiency of the heat exchanger, reheating is usually not necessary. After basic setup by the installer, the unit requires no further adjustment. Demands on the user are minimal. Filter replacement is recommended at least once a year. The design of heat recovery units and their use in buildings with category B gas appliances (gas boilers and open chamber water heaters) or with open hearth appliances burning solid or liquid fuels with flue gas exhaust to the chimney is prohibited. Ventilation must also comply with the building fire safety regulations and must not contravene fire regulations.

Information

The design of the unit is intended for the reconstruction of flats in apartment buildings and for the new construction of apartment buildings.

Share on Facebook

Share on Facebook Tweet

Tweet Send email

Send email