Cabinet

is welded from steel sheet, with flanges for circular pipes, galvanized. Operating temperature is -20 to +40 ˚C. The engine lies in the air stream.

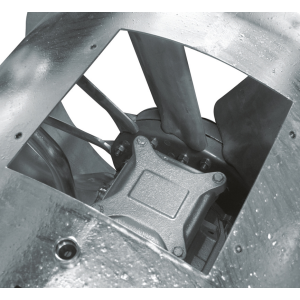

Running wheel

is made of Al alloy. The impeller is statically and dynamically balanced. The adjustment of the impeller blade angle is made by the manufacturer and must not be changed.

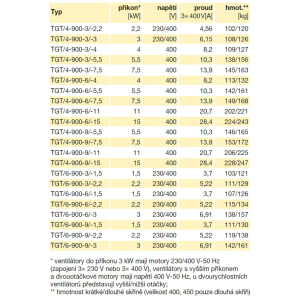

Motor

is asynchronous with short armature. Motor insulation is class F, motor protection is IP55. The ball bearings are sealed, with grease packing for life. Up to 3 kW motors with 230/400 V-50 Hz, for higher outputs 400 V-50 Hz (also two-speed motors).

Screwdriver

is located on the motor or on the fan housing and is of explosion-proof design.

Speed control

Fans cannot be electrically or electronically controlled. Selected types can be regulated using a frequency converter (PTC thermistor required). The exact solution must be consulted with the technical department.

Flow direction

is from impeller to motor (i.e. direction B, from motor to impeller is direction A).

Noise

emitted by the fan is listed in the fan performance characteristics in the selection software.

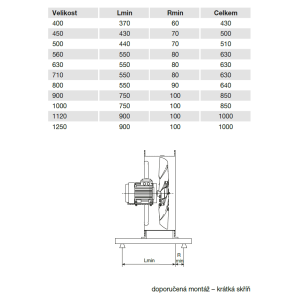

Mounting

fans in each motor axis position. The casing must not transmit mechanical stresses from the ductwork. A flexible connection to the piping must be used. Fan accessories and dimensions will be provided on request.

Accessories

- ACOP Ex flexible coupling

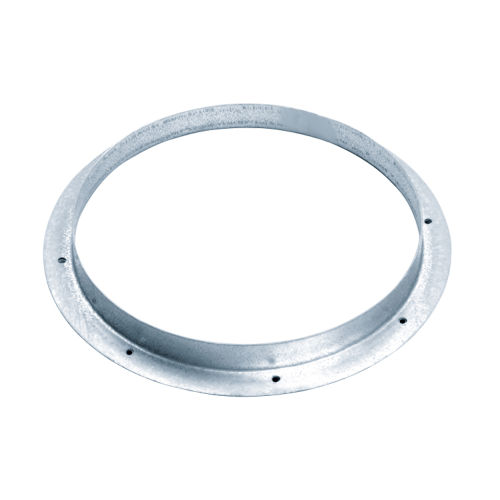

- BRIDA loose flange

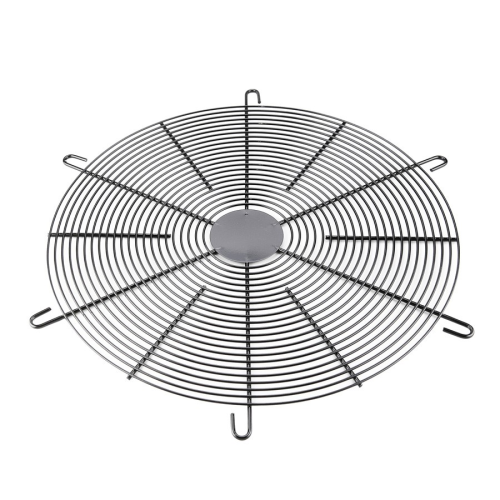

- DEF-A inlet protection grille

- DEF-D discharge protection grille

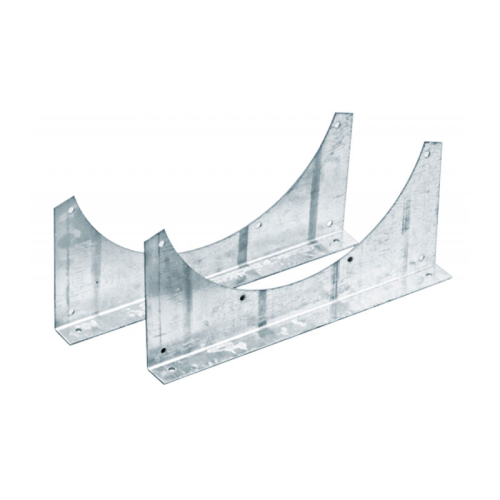

- PIE mounting bracket

- TAD inlet nozzle

- WSK Ex plastic self-cleaning louvre

Instructions

Please note, the fans are in a special design for CR. Spare parts supplied by the manufacturer or trade organisations as standard cannot be used. Please request information on delivery times. The values In, Ia/In and te specified in the fan certificates are decisive for the installation of the safety elements and thus the safe operation of the fans. These values must be checked carefully after delivery of the fan.

Share on Facebook

Share on Facebook Tweet

Tweet Send email

Send email