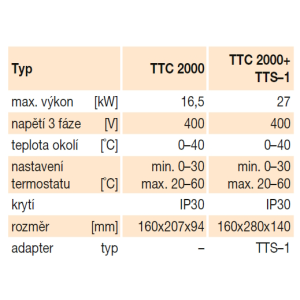

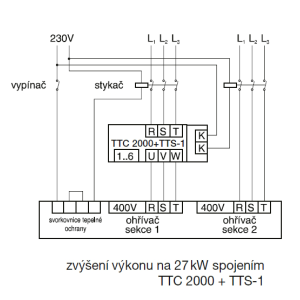

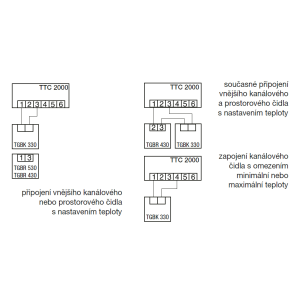

The TTC 2000 triac electric heater controller is designed for continuous control of electric heaters up to 16.5 kW. In conjunction with the TTS-1 adapter, it is designed for control up to 27 kW in two stages - continuous 16.5 kW, fixed 13.5 kW. It is necessary to connect an external temperature sensing sensor to the controller, e.g. TGBK 330 or TGBR 430, TGBR 530. It is also possible to connect a second sensor for temperature limiting (max. or min.), a time switch for switching to night drop (4 °C difference), a coupled second controller, or to connect an external 0-10 V control signal.

Installation

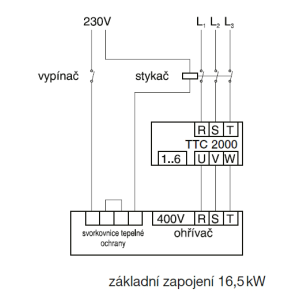

The connection and earthing of the electrical equipment shall comply in particular with EN 33 2190, 33 2000-5-51, 33 2000-5-54. The work may only be carried out by a worker with professional qualifications in accordance with ČSN 34 3205 and Decree No. 50-51/1979 Coll. The supply wires (400 V 50 Hz) are connected to the power supply terminals marked RST and the cable from the heater to the UVW terminals. The supply voltage to the TTC 2000 should be routed through a contactor that is controlled by the heater thermal protection and the fan run switch. Depending on the selected controller-sensor configuration, the function switches must be set to the correct position. After removing the front panel, the terminals are accessible - for the power supply (RST,UVW), for the control circuit (1, 2, 3, 4, 5, 6), the function switches (1 - 8), the control element for setting the limit temperature, possibly the terminals of the TTS-1 adapter. The controller must be mounted vertically so that air can flow around the cooling fins of the triacs. The total heat loss of the triacs is approximately 50 W. Do not install near other heat sources.

Caution

The heater must have both safety and operating thermostats connected. The load in each phase must be uniform.

Share on Facebook

Share on Facebook Tweet

Tweet Send email

Send email