A common question from installers is the suitability of matching a lone louver damper to an axial fan.

A variety of lone outdoor louvered damper types can be found in the Elektrodesign range. The PER range is made of plastic and is suitable for maximum speeds up to 12 m/s, the TRK range with aluminium sheet blades is suitable for speeds up to 7 m/s, and the TRKS range with steel sheet blades and plastic axle bearings is suitable for speeds of approx. 17-19 m/s.

From the above it follows that the above mentioned louvre dampers alone often cannot be used without additional measures directly on the discharge of axial fans which have 2P or 4P motors (1400, 2800 rpm) depending on the diameter.

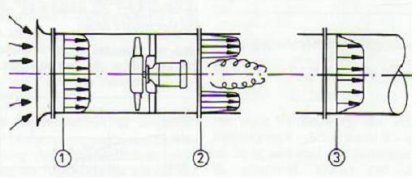

In axial fans there is another problem, namely the inhomogeneous velocity field at the discharge. That is, the speed is different at the fan axis, in the space between the case and the motor, and at the case wall. Another problem is that the discharge stream is rotating. The effect of this can be seen in louvered dampers, where the individual blades are opened unevenly, or some blades point down, others up, or even oscillate.

For example, if we assume a steady flow velocity in the duct of about 17 m/s (about 30000 m3/h) for a TCBT/4-800 fan with a short duct, we actually measure velocities of over 25 m/s behind the fan. These velocities will reliably destroy the attached damper, which we would place directly on the discharge.

The velocity field can be reduced by attaching a fixed fan grille to the fan discharge, by attaching it to the chamber (where the pressure and velocity relationships will be equalized), or by using a rectifier on the discharge.