In order to make the most of the fan's performance parameters, a few basic rules must be followed when designing and installing the fan:

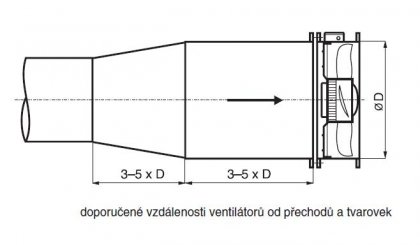

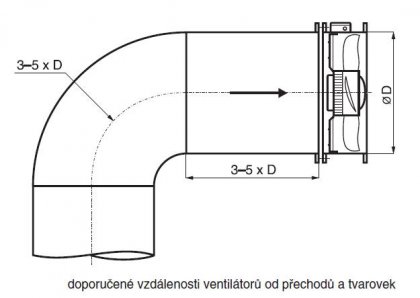

- In order to minimize air inlet and outlet losses from the fan, minimum clearances to fittings and cross section change points must be maintained.

- Accessory parts, fittings, or bends that cause the airflow to be pulled away from the impellers are not permitted to be directly attached to the fan. This results in reduced fan performance and increased noise. Axial fans may also shift the operating point to an unstable region. Continuous operation of axial fans in an unstable region can lead to damage to the fan.

- In principle, a distance of 3-5 times the fan diameter from transitions and curves should always be maintained.

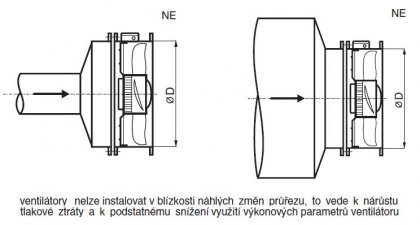

- It is not permissible for the fan to be close to sudden changes in cross section. These locations can cause a dramatic increase in pressure drop, resulting in a significant reduction in fan performance utilization. When using a diffuser at the outlet of axial fans, careful attention must be paid to the design, as poor design does not lead to improved fan performance, but rather to deterioration. The length of the diffuser with the core is recommended to be 2x the fan diameter.

- To reduce losses, TAD nozzles should be used on the fan intake. Flexible couplings must be fitted taut and without creases. The distance of the fan intake from the walls should be at least 1x the fan diameter.

Attention:

When, for example, parallel coupled axial fans operated separately are designed for garage ventilation, the following recommendations must be observed. The fans must be separated by dampers. A fan that is not in operation is disconnected from the system by dampers. Individual parallel branch lines shall be as long as possible, with equal pressure drop, and separately operated fans shall operate outside the unstable area with a margin of safety.