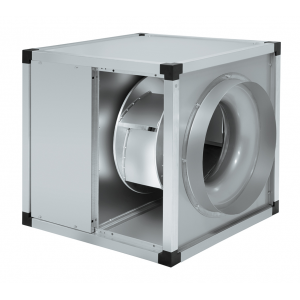

Cabinet

It is made of galvanized steel sheet, sandwich design. The cabinet is internally coated with a layer of soundproofing material. The fan is mounted in the enclosure on sprung profiles to reduce vibration transmission. A circular inlet is fitted on the cabinet for connection of flexible hoses or circular ducting. There is a square hole on the discharge where a circular pipe reducer, supplied separately, can be connected. The cabinet contains a tray for the drainage of the fat condensate, the condensate drain must be mounted in accordance with the position of the fan and the appropriate inclination of the fan towards the throat must be selected.

Running wheel

is radial with backward curved blades. The impeller is free-running, without spiral housing, statically and dynamically balanced.

Motor

EC motor with thermal overload protection. KABB fan motors are 1-phase for 230 V, KABT are 3-phase for 400 V. IP55 protection, insulation class F, motor ambient temperature -20 °C to +50 °C (KABB) or -20 °C to +40 °C (KABT). The motor is located out of the air stream, operating air temperature from -20 to 100 °C.

Clamps

is located on the fan housing with integrated potentiometer and safety off/on switch.

Speed control

is performed by a potentiometer located in the fan terminal block or by an external REB Ecowatt control. In addition, an analogue 0-10 V control signal from a temperature, humidity or CO2 sensor.

Mounting

is carried out with the motor axis horizontal and the condensate tray underneath, due to the design, fan operation and inspection activities.

Instructions

Fans are suitable for air handling applications where low fan noise is advantageous. The fans are particularly suitable for large capacity kitchens, for ventilation of restaurants, sports halls, hospitals, warehouses and swimming pools.

Share on Facebook

Share on Facebook Tweet

Tweet Send email

Send email