Cabinet

It is made of galvanized sheet metal with round necks on the front sides of the recuperator. There are removable circular covers on the sides of the recuperator which can be interchanged with the circular throats as required. Condensate drains are installed at the bottom of the recuperator on the waste branch (the condensate drain on the air side before the recuperation can be blinded).

Recuperation

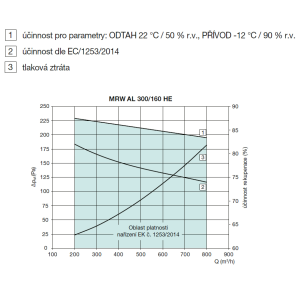

The aluminium plate heat exchanger meets the requirements of EC Regulation 1253/2014 and is built into the recuperator cabinet. Sizes 280, 350 and 500 can be supplied with a bypass damper which is on the fresh air supply side. The bypass damper servo drive is not included in the delivery.

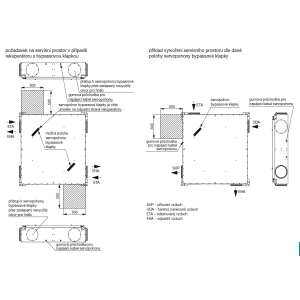

Mounting

Only in a horizontal position (under the ceiling) with a 1° inclination to the waste drain pipe. The condensate drain must be connected via a siphon to the sewer pipe. For the recuperator variant with bypass damper, a service space must be provided for access to the bypass damper actuator. The servo drive power cable must be routed through a rubber grommet to the outer jacket. Other than the horizontal position, the technical department of Elektrodesign ventilators s.r.o. must be consulted.

Options

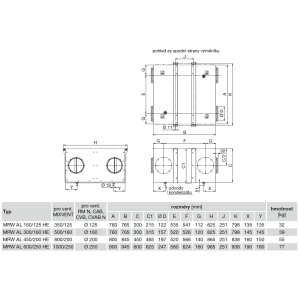

- MRW-AL H / Ø D HE - heat recovery exchanger without bypass damper, H - type designation, Ø D - throat dimension

- MRW-AL H / Ø D BP HE - heat recovery exchanger with bypass damper, H - type designation, Ø D - throat dimension

In the case of the variant with bypass damper, the bypass is located on the supply air side. The bypass damper actuator is located on the outlet side of the recuperator. The location of the bypass damper actuator can be changed as required. Access to the actuator is through a blinded unused throat opening. If the recuperator is covered by a soffit, a service hole must be created in the soffit for possible servicing of the bypass damper actuator. The minimum size of the service hole is shown in the figure below.

Instructions

The exchanger is resistant to corrosion and damp environments. It cannot be used in explosive environments, environments with chemical fumes, solvents and aggressive substances. To reduce the risk of contaminants clogging the exchanger, air filters must be installed on the fresh (outdoor) air and exhaust (indoor) air sides.

Information

Aluminum heat exchangers are suitable for modular systems with MIXVENT-TD, RM N, RK, CVB, CVAB N, CAB fans. The exchangers are universally applicable for central and decentral ventilation systems. The design is particularly suitable for building systems in circular ducts.

- low purchase costs

- high corrosion resistance for humid environments without aggressive substances

- easy maintenance

- cannot be used for explosive environments and solvent vapours

- temperature resistance -25 to +80 °C

Share on Facebook

Share on Facebook Tweet

Tweet Send email

Send email