| A | B | C | D | E | F | G |

|---|---|---|---|---|---|---|

| 1465 | 1100 | 785 | 1200 | 600 | 132,5 | 92,5 |

with dimensions

| A | B | C | D | E | F | G |

|---|---|---|---|---|---|---|

| 1465 | 1100 | 785 | 1200 | 600 | 132,5 | 92,5 |

with dimensions

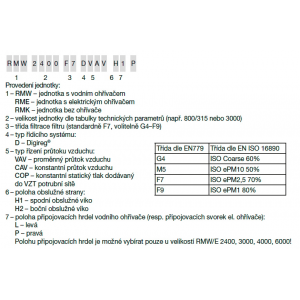

Cabinet

The 45 mm thick wall panels are made of galvanized steel sheet with external painting in RAL 9002. The panels are internally filled with sound and thermal insulation made of non-combustible glass mineral wool. For ease of servicing, the unit cabinet is equipped with removable doors with locks. The frame of the unit is made of aluminium profiles, the wall panels are screwed into the frame. The water heater connections are routed to the outer casing of the unit. The cabinet is fitted with 4 hinges with Ø 12 mm holes for underfloor mounting of the unit.

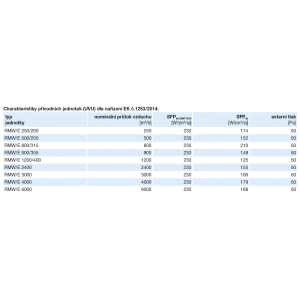

Fans

The 45 mm thick wall panels are made of galvanized steel sheet with external painting in RAL 9002. The panels are internally filled with sound and thermal insulation made of non-combustible glass mineral wool. For ease of servicing, the unit cabinet is equipped with removable doors with locks. The frame of the unit is made of aluminium profiles, the wall panels are screwed into the frame. The water heater connections are routed to the outer casing of the unit. The cabinet is fitted with 4 hinges with Ø 12 mm holes for underfloor mounting of the unit.

Motor

The EC motor is directly mounted on the fan impeller. The fan motor can be continuously controlled by an external 0...10 V or PWM signal. The motor is equipped with its own built-in thermal protection. The electric motor is IP44 rated.

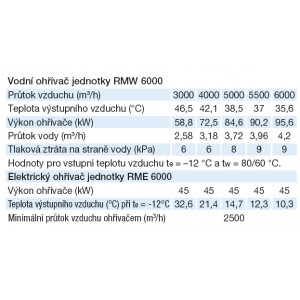

Heater

The water heaters are designed for a heating water temperature gradient dT = 20 K (80/60 °C) for an inlet air temperature te = -12 °C/90 % r.v. at nominal air flow. Electric heaters are designed for an inlet air temperature te = -12 °C/90% r.h. at nominal air flow and are equipped with an operating and emergency thermostat.

Filter

The unit contains one or more filter elements of filtration class F7 (optional filter class G4 to F9), which are situated in one filter wall. The filter is made of polypropylene filter material. Access to the filters is via the inspection door on the service side of the unit. In case of multi-stage filtration, the unit can be supplemented with MFL filter cartridges with MFR filter inserts, which are designed for installation in pipes.

El. connection

The supply voltage of the units is 1 x 230 V / 50 Hz or 3 x 400 V / 50 Hz and depends on the equipment of the unit. Supply cables, cables to sensors, power cables to fans are fed into the unit via plastic grommets in the wall of the unit, which are not included in the unit delivery. The electrical heater terminal block on RME units is accessible by removing the outer cover. The electric fan motor has the supply power cable routed to a plastic junction box with a terminal block located inside the unit.

Regulation

The unit is supplied without regulation as standard. If required, the unit is equipped with Digireg® regulation. In case the unit is equipped with a MaR system directly from the factory, all sensors and actuators are electrically connected and tested. The control box is placed on the wall of the unit according to the actual space requirements of the specific project (the location of the MaR control box must be specified in the order).

Noise

Noise shown in the tables represents the sound power levels at the unit intake and discharge with A-weighting correction and the sound pressure level at 1 m from the service side of the unit (in the free field Q = 2).

Variants

- RME - with built-in electric heater and filter

- RMW - with built-in water heater and filter

- RMK - supply unit with filter without heater

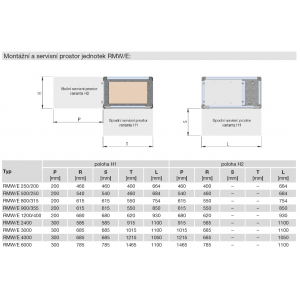

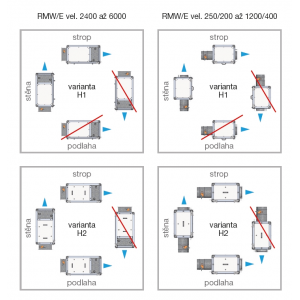

Mounting

Mounting is possible in horizontal position with the service side from the side of the unit (marked in unit code H2) or from the bottom of the unit (marked in unit code H1). It is also possible to distinguish between right (P) and left (L) versions according to the position of the water heater outlets or the position of the electric heater connection terminal (for sizes 2400, 3000, 4000, 6000). The L or P position is determined by looking at the front inlet face of the heater in the direction of air flow. A handling area is required next to the unit for removing the lid and filters and for making periodic electrical inspections.

Information

The unit is designed for ventilation of commercial premises. The delivery of the unit to the outdoor environment should be consulted.

Warranty Terms

The RME, RMW, RMK Ekonovent® equipment including the DVAV, DCAV and DCOP control system must be commissioned solely by the Seller or a person designated by the Seller to do so. Failure to comply with this condition shall result in the termination of the Buyer's rights under the defective performance and the Quality Warranty. Further conditions are set out in the Seller's Complaints Procedure.

Share on Facebook

Share on Facebook Tweet

Tweet Send email

Send email